DIVINE METAL INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DIVINE METAL INDIA

Aluminium Bronze

Aluminium Bronze is used in many heavy duty applications which require good ductility, tensile strength, deformation in overloaded situations, weldability etc. In Aluminium Bronze, Aluminium is the main alloy metal added to copper. Aluminium bronzes are more recognized for their corrosion resistance and high solidity. Aluminium bronzes are also resistant to corrosion in sea water.

Applications :

Aluminium bronzes are majorly used in applications where their resistance to corrosion makes them preferable to other engineering materials.

These applications include:

• Plain Bearings

• Valve components

• Engine components

• Guitar strings

• Landing gear components on aircraft

• Underwater fastenings in naval architecture

• Ship propellers

Aluminium Bronze Scarp

We, Divine Metal India engaged in manufacturing and supplying of Aluminium Bronze Scrap. This product is manufactured by using high-quality raw material procured from reliable vendors of the market and its features like optimum strength, High strength ability to bear pressure, durability low maintenance and corrosion resistance.

Aluminium Bronze Scarp in addition to this, we stringently test each product on multiple stages to ensure their flawlessness and quality.

Divine Metal India provides Aluminium Bronze Scrap which is very useful in making different kinds of sturdy products such as bars, plates, machine parts & components, pipes and sheets.

Aluminium Flat Bar

Aluminium Flat Bar is available in various alloys which offers a wide range of machinability, weldability and helps in corrosion resistance.

High strength Aluminium Flat Bars are widely used in Aerospace applications. In Marine applications, high corrosion resistance aluminum alloys are commonly used.

Aluminium Flat Bars are mainly used in applications like:

- • Aircraft

- • Automobiles

- • Construction

- • Transport

- • Flashlights

- • Jigs

Aluminium Bronze Pipe

Aluminum Bronze is used for the combination of high strength and excellent corrosion and wear resistance to make a pipe.

Divine Metal India Aluminium Bronze Pipe is made of using the best quality optimum-grade material and advanced technology. Although this alloy is supplied in the cast condition which can be heat-treated to enhance its mechanical properties for more demanding applications.

Divine Metal India provides Aluminium Bronze Pipand its features are high strength excellent corrosion resistance, dimensionally accurate and toughness etc.

Divine Metal India also provides customized according to customer's size and material requirements.

Phosphor Bronze Bushes

Phosphor bronze is the alloy used for bolts, springs and for different other items that are used in situations where resistance to wear, fatigue and chemical corrosion are required. Bronze is a resourceful material used for bushings as it comes in many alloys and compositions.

Phosphor bronze bushes have longer lifespans and resist wear and corrosion, shock and impact. The phosphor bronze Bushes have high fatigue resistance, excellent formability and solderability, excellent spring qualities and high corrosion resistance. Phosphor bronze bushes are basically used for Electrical items, spring washers, diaphragms and corrosion resistant Bellows.

Cast Iron Castings

Cast Iron Castings have become a prominent in the Engineering sector having wide range of applications like Piping, Machines, Cylinder heads, automotive industry parts, Cylinder blocks, and Gear box cases. Cast Iron Castings is widely used for its quality features like good fluidity, Castability, relatively low meting point, excellent machinability, resistance to deformation and wear resistance.

Cast Iron Castings is majorly used to make various types of utensils, pans, pots that are used for heating purposes. Cast Iron Castings maintains Heating temperature. Once a cast-iron pan is hot, it will maintain the good temperature effectively than stainless steel. Cast Iron surface dole out heat from the stone evenly. Cast Iron is used in Bakery for baking purpose and even to make stoves from a single piece of mould.

Cast iron was prominently used in the Foundries which manufactured the machinery used industrial and agricultural sector. Cast iron was also widely used for making frame and fixed parts of machinery which included spinning and later weaving machines in textile mills. Cast iron castings played a major role to construct tall buildings without thick walls required to build masonry buildings of any height.

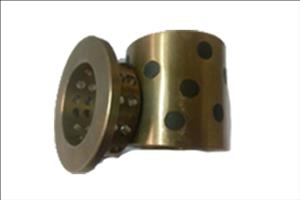

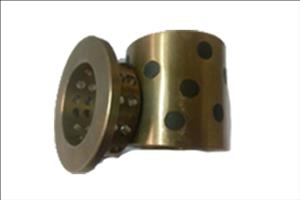

Cast Iron Casting Machining

We, Divine Metal India are engaged in manufacturing and supplying of Cast Iron Casting Machining which is manufactured using quality raw material.

Cast Iron Casting Machining structure AST650 Cast Bronze with solid lubricant plugs. The AST650 Series Bushings are made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and also the solid lubricants gives for self-lubrication. The bushing shows excellent performance without pre-lubrication under the conditions of extreme high/lower temperature with low speed.

Divine Metal India provides Cast Iron Casting Machining which gives maintenance-free bushing solution, particularly for high load intermittent of oscillating motion. This Cast Iron Castings machining is mainly supplied to manufacturers of mud pumps, hammer unions, injection molding machine, press machines, machine tools, valves and ships.

AST650 Series Features

• Work without oil for long periods

• Extremely high load capacity with best anti-wear and lower friction

• Appropriate for low speed and high load

• Suitable for reciprocating, oscillation, motion where an oil film is difficult to create

• Good chemical resistant and anti-corrosion characteristics

Applications for the AST650 Series

This kind of bushing can be used under dry, warm temperature, high pressure, corrosive, water, or different chemical environments when oil cannot be introduced. The AST650 Series bushings are widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in the metallurgy industry, mining equipment, ships, turbo generators, hydraulic turbines, and injection molding machines.

ST650 Series Structure AST650 Cast Bronze with solid lubricant plugsThe AST650 Series Bushings are made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide for self-lubrication. The bushing shows excellent performance without pre-lubrication under conditions of extreme high/lower temperature with low speed. This material provides a maintenance-free bushing solution, particularly for high load, intermittent of oscillating motion.

AST650 Series Features

• work without oil for long periods

• Extremely high load capacity, with good anti-wear and lower friction

• appropriate for low speed and high load

• Suitable for reciprocating, oscillation, motion where an oil film is hard to form

• Good chemical resistant and anti-corrosion characteristics

Typical Applications for the AST650 Series

This kind of bushing can be used under dry, high temperature, high pressure, corrosive, water, or other chemical environments when oil cannot be introduced. The AST650 Series bushings are widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in the metallurgy industry, mining equipment, ships, turbo generators, hydraulic turbines, and injection molding machines

Gunmetal Casting

Gunmetal is an alloy where Lead contributes 2% of its share replacing the Zinc which makes the alloy easy to cast. Gunmetal Casting is used for Gears and Bearings. Gunmetal Casting is originally used for making guns and now has largely been replaced by steel. Gunmetal Casting is used to make gears, valves, steam and hydraulic castings, statues and various small objects, such as buttons. Gunmetal Casting is resistant to corrosion from salt water and steam.

The standard uses of Gun Metal Castings are bushes, valves, valve bodies, valve guides under corrosive marine conditions, Pressure tight bearings, Bearings for aero engines, pumps and pump fittings, Gear and worn wheels, diesel engines, rolling mills, electrical generators etc.

Gun Metal Castings have features like Shock resistance, High ductility, efficient performance, outstanding material strength.

Phosphorous Bronze Castings

Phosphorous Bronze Castings are used for springs, bolts and various other items which are used in situations where resistance to fatigue, wear and chemical corrosion are required. The alloy is additionally utilized in some dental bridges and cryogenics.

Phosphorous Bronze Casting’s features are like sturdy construction, zero maintenance and a perfect combination of electrical & low thermal conductivity to ensure excellent electrical connection to devices at low temperature without adding excessive heat.

We, Divine Metal India are engaged in manufacturing and supplying of Phosphorous Bronze Castings which are made of using supreme-grade quality bronze, phosphorous and sand.

These phosphorous bronze castings are highly recognized by people due to their dimensional accuracy.

Stainless Steel Rods

Stainless steel Rods are hard and tough. Stainless steel Rods are magnetic, ductile and also retains its strength and cutting edge regardless of temperature. Stainless steel rods (stainless steel round bar) can also be threaded to securely hold objects together. Stainless steel Rods are not a good conductor of heat and electricity,

There are five major types of stainless steel rods like Duplex, Precipitation Hardening, Austenitic, Ferritic and Martensitic.

Metal rod is necessary in any industry. Stainless Steel bars are widely used in a various industrial sectors like fabrication, cement, automotive, heavy earth moving equipment and construction, paper and pulp, textile, defense, shipbuilding, etc. Stainless Steel Rods are majorly used in building foundations, parking garages, barrier walls, highway bridges, tunnels and marine facilities.

Super Duplex Component

Super Duplex Component is a Stainless Steel primarily used in oil and gas applications. Super Duplex alloys are classified by a high molybdenum and chromium. The content of high chromium and molybdenum render Super Duplex Steel a high resistance to acids that could cause pitting and crevice corrosion. This gives Super Duplex Component a high impermeability which enables to have better resistance to corrosion cracking and erosion.

Super Duplex Component also has a low thermal expansion and high thermal conductivity than conventional austenitic stainless steels. Due to the attributes like durability and corrosion resistance, Super Duplex Component is used for parts directly exposed to corrosive substances like chemical and Sea water.

Super Duplex Components have high demand for pipes used in Oil and Gas industry, high strength wiring solutions, utility and industrial systems, structural and mechanical components, heat exchangers and cargo vessels. Super Duplex Components are also best suited in many on-shore and off-shore applications.

Titanium Parts

Titanium is an alloying agent comprised of different metals like Iron, Aluminium, and Molybdenum etc. Titanium parts are mainly used in Spacecraft, Aircraft and missiles as they have the low density and ability to withstand extreme temperatures.

Titanium parts are recognized for their solidity and weight. Titanium parts are corrosion resistant against water and salt, ductile and have high melting point. Titanium parts are corrosion resistant for Structural components, Aircraft Engines and Controls.

Titanium parts are majorly used in applications like Spacecraft, Jet Engines, Bearings, Military Equipments, Body armor and other high-tech products.

Horizontal Centrifugal Casting

Clients can purchase from us an extensive array of Centrifugal casting Horizontal, which is designed by our skilled professionals using quality approved basic materials. The raw material used to manufacture this product is procured from reliable vendors in the industry in observance with international quality standards. This range is broadly demanded due to its accurate dimensions, high performance, easy to handle features, corrosion resistance, easy installation and durability. Centrifugal casting Horizontal is available in standard as well as customized options as per the clients requirements.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.